| Sign In | Join Free | My udpf.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My udpf.com |

|

Brand Name : MG

Model Number : MG-001

Certification : CE BV ISO 9001:2008

Place of Origin : Henan, China

MOQ : 1 set

Price : 5000

Supply Ability : 90 sets/month

Delivery Time : 10 working day

Packaging Details : wooden box

Condition : New

Voltage : 220 380V 415V 440V Customized

Power : 15-25KW

Weight : 3 T

Dimension(L*W*H) : 4500X4000X2800mm

Features : simple and cheap

Key Selling Points : Easy to Operate

Advantages : Low cost and high output

Color : White or customized

Technical support : Life-long service

Formula of different mortar : Provided

OEM&ODM : Accepted

Batching and weighting : Manual+simple Automatic

Application : Dry construction mixture making

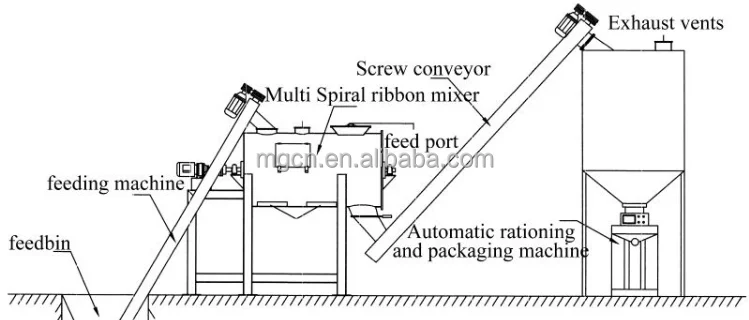

| Dry mortar plant parameters | |||||

| Model | Out put | Occupied area | Equipment Height | Manpower | Batching and packing |

| Simple dry mortar plant | 1-3t/h | 20m2 | 3-4m | 2-3 Person | Manual batching Automatic packaging |

| Improved dry mortar production line | 4-5t/h | 20m2 | 3-5m | 2-3 Person | Manual batching Automatic packaging |

| Semi-auto dry mortar plant | 6-8t/h | 50-60m2 | 6-8m | 3-4 Person | Manual batching Automatic packaging |

| Automatic dry mortar plant | 8-30t/h | 50-60mm2 | 8-13m | 3-4 Person | Manual batching Automatic packaging |

I Small investment and best for individuals.

II Small footprint, ordinary houses can build the factories.

III Easy to operation, 2-3 people can make it.

IV High yield, the output is 3-4T/H usually, to reach 20-25T per day.

V Easy to operation and maintenance.

![]()

![]()

Pre-sale service

1.Upon got your inquiry, We will reply to you in 24 hours.

2. High quantity and quantity assured.

3.Favorable price as we are manufacturer.

4.Provide professional technical and project solutions online or through telephone .

5. Well-trained and experienced staff to answer all your inquiries in fluent English and Russia.

6.OEM & ODM is welcomed. OEM brand is available.

7.Assist clients to prepare for the first construction scheme and supply foundation drawing.

2.Oversea installation and provide technical exchange, train client to operate the machine.

3.Supply spared and accessory parts at favorable price for long-term.

4.Spare part are original, authentic, good quality.

5.They can be available from stock, and sent to clients, immediately by sea, guarantee clients to receive it in shortest time.

6. Providing following up after-sale service.

![]()

![]()

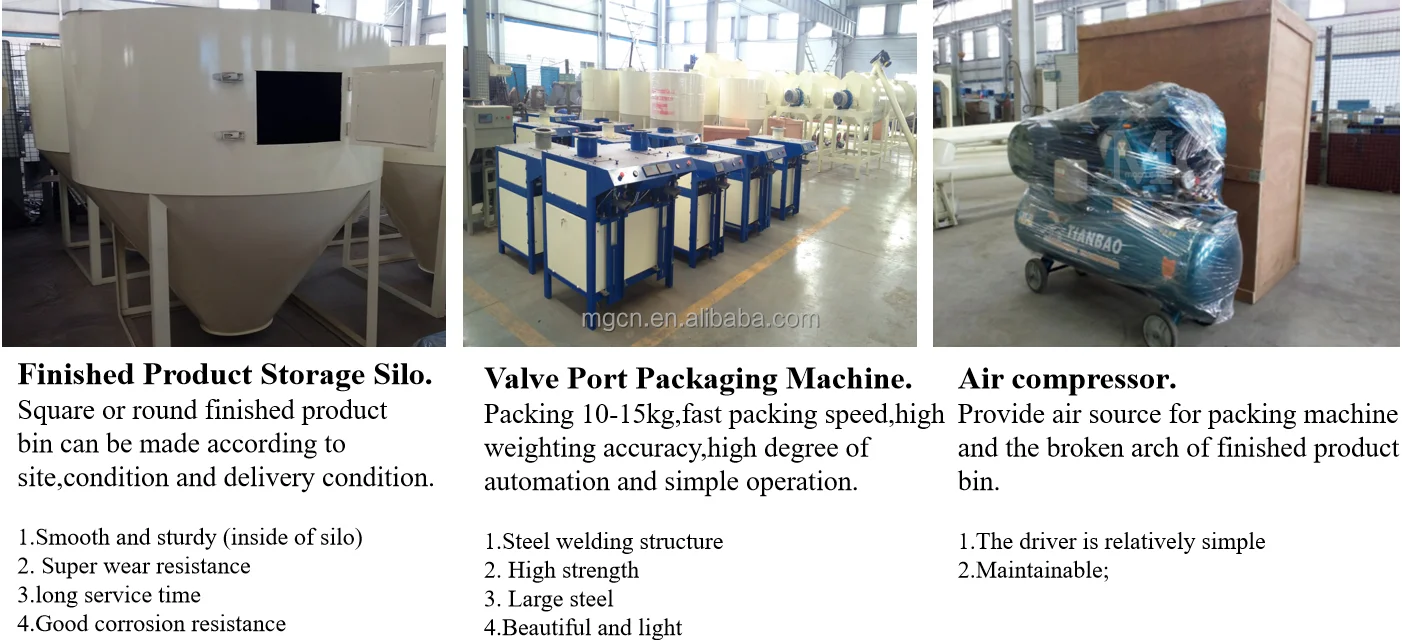

Dust Collector

Automatic Packaging Machines

Disc feeder

Vibrating Screen

Raymond Mill

Belt Conveyor, etc.

C. Drying equipment.

Rotary Sand Dryer

Three Cylinder Rotary Sand Dryer

D. New type perlite expansion equipment.

High-output perlite expansion furnace

Efficient vermiculite expansion furnace

|

|

Simple Automatic Dry Mortar Machines Tile Adhesive Wall Putty Making Machine Images |